- Activant's Greene Street Observer

- Posts

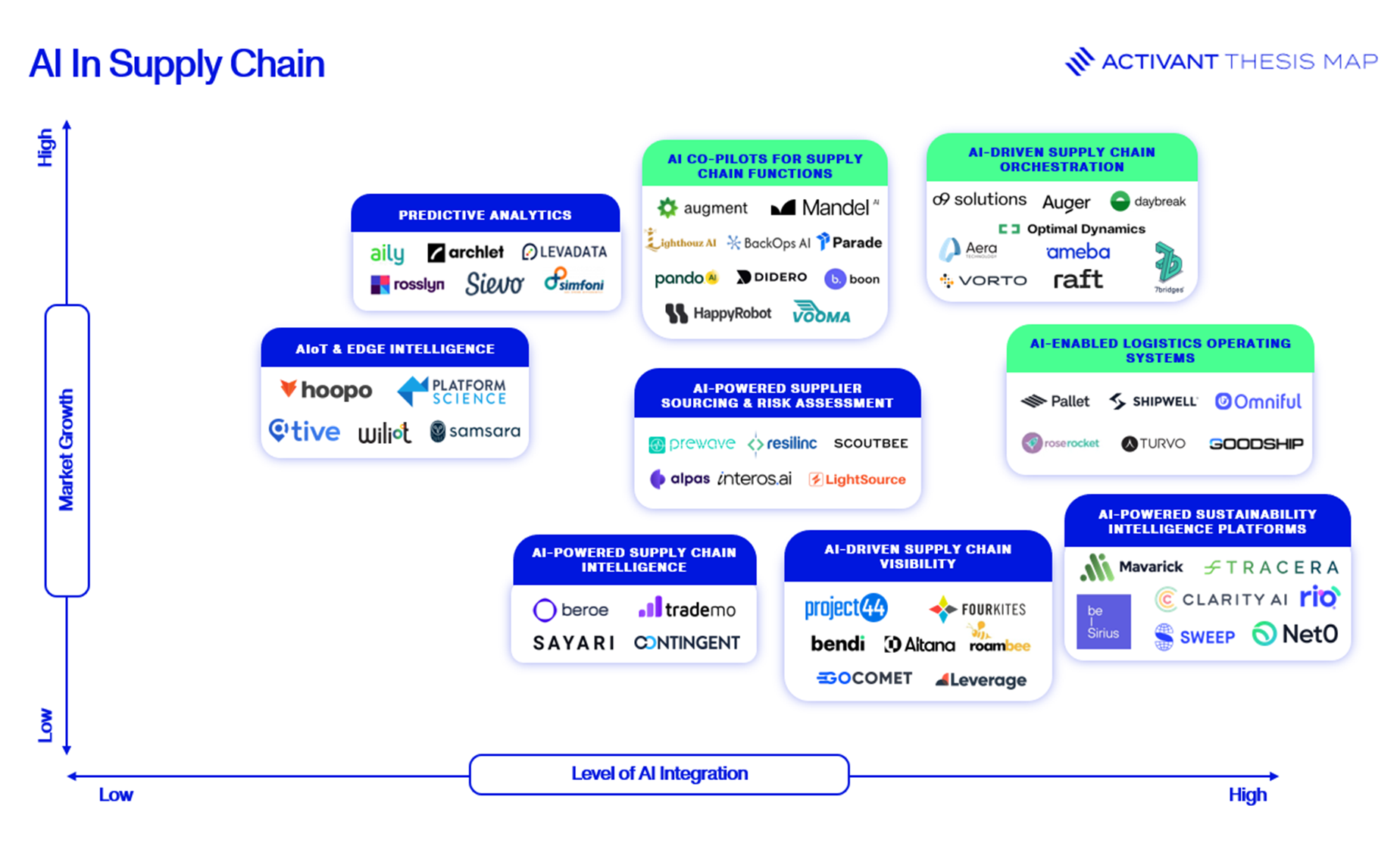

- AI is Rewriting the Rules Of Supply Chain

AI is Rewriting the Rules Of Supply Chain

Unlocking a $65 billion opportunity

Introduction

Supply chains are under pressure from multiple factors, which include rising costs, labor and material shortages, volatile demand, shifting customer expectations, geopolitical tensions, regulatory uncertainty, and mounting sustainability demands in many markets. These myriad challenges show no sign of slowing, with supply chain disruptions jumping 38% in 2024, signaling a renewed wave of instability across global networks. The cost of this is real: logistics inefficiencies can add up to as much as $95 billion in annual losses, impacting B2B companies the most.

In a world of increasing global tariffs, cross-border logistics is made even more complex. Extensive tariffs on US imports, such as the 25% increase on auto imports and additional levies on countries such as China, Canada and Mexico, are compounding supply chain issues.

Supply chains are at the core of the global economy, yet they remain one of the most labor-intensive and under-digitized functions. While automation has made some inroads, it failed to deliver on its potential. However, AI appears poised to help alleviate some of these pain points and GenAI represents the next frontier for transformative workflow improvements and operational efficiency.

Global Supply Chains Are Fragmented

Modern supply chains are increasingly complex. They’re also highly fragmented due to their cross-border nature and the fact that they operate on unstructured data. Today, over 80% of data exchanged in supply chains is unstructured. The problem with this is that the core operating systems—ERPs, CRMs, marketplaces—were built to handle structured data. In addition, Electronic Data Interchange (EDI) systems are outdated and inconsistently adopted. This results in fragmented communication and limited real-time visibility. Incorrect or siloed data can lead to significant financial losses, with companies potentially losing up to 30% of revenue annually. This is partly due to the drain on employee productivity that results from inefficiencies caused by data isolation. Despite the urgent need for innovation, logistics remains slow to evolve and 76% of digital transformations fell short of key goals, according to Gartner. Legacy systems and manual workflows still dominate, with nearly 50% of supply chain leaders not investing meaningfully in core digital tools like Warehouse Management Systems (WMS) or Transportation Management Systems (TMS).